Chinese battery maker Narada Power Source has boosted the performance of an advanced lead-acid battery by reducing the electrolyte and enhancing the partial state-of-charge window.

The company also tweaked the re-charge algorithms to allow its advanced deep-cycling valve regulated lead-acid (VRLA) battery to achieve more than 26,000 power-assisted cycles.

Subsequent laboratory results indicated a possible cycle life of more than 230,000 cycles.

The VRLA battery was adapted for power-assist and power-recovery duty in battery/diesel hybrid port cranes. The battery was operated at a state-of-charge of about 20% of rated and an associated electrolyte density below 1.20g.ml-1.

Initial tests found carbon additives offered minor benefits compared to electrolyte concentration and the state-of-charge at which the power-assist and power recovery operation was carried out.

The company, a member of the Advanced Lead-Acid Battery Consortium (ALABC), released the results following the conclusion of the three-year project.

The investigation found that while carbon additives were beneficial, they were not enough to accept and deliver power in 15-second bursts for more than 14,000 cycles (a month’s 24/7 usage).

This performance criteria was to mimic the real-world use of the crane power-assist/power-storage operation that requires the battery be operated in a PSoC.

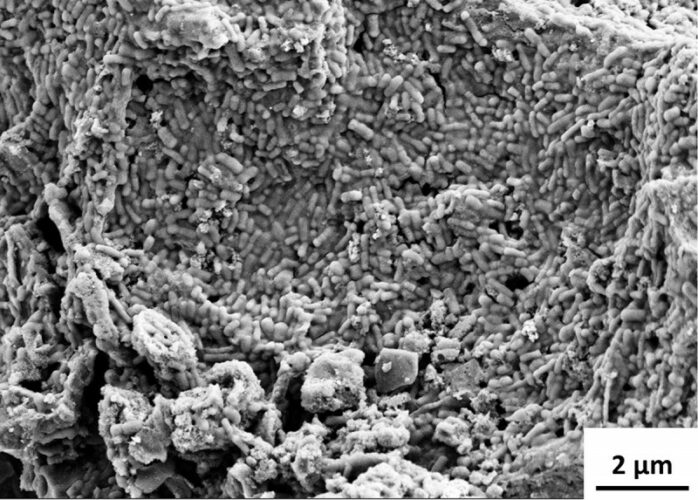

The company has dismissed use of multiple allotropes of carbon ranging from carbon black, graphite, activated carbon, milled carbon fibres and multilayer graphene incorporated in the negative active mass.

These were avenues first explored in Start-Stop SLI batteries operating in PSoC.