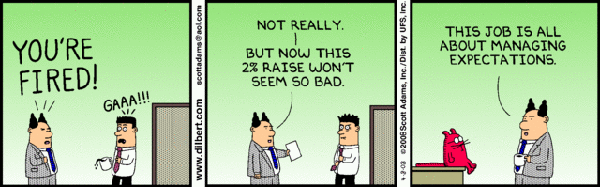

The difference between success and failure is often a matter of perspective. Dr Mike McDonagh recounts a story of how an unrealistic delivery timescale caused a success to be deemed a failure, at least in the short term.

There is often a thin dividing line between success and failure when completing projects. One of the reasons for this is down to the criteria that we use to measure success. Very often we fail to see success under our noses simply because we are unaware of how to recognise it. This cautionary and fact-based tale shows how a very young and naïve engineer, who successfully completes a worthwhile money-saving project, ends up in trouble for missing the implementation deadline. The end outcome is that she is perceived, perversely, as losing money for the company, due to not implementing the proposed cost savings on time.

The perception of failure and success is often a matter of perception or even self-promotion. According to Kipling, you should treat both success and failure as imposters in order to be a balanced person— which is all very well in an ideal world. However, in order to progress in any career, you have to be seen to be successful. With some intelligence, it is possible to manage the expectations of those people who are important to your personal standing in a company.

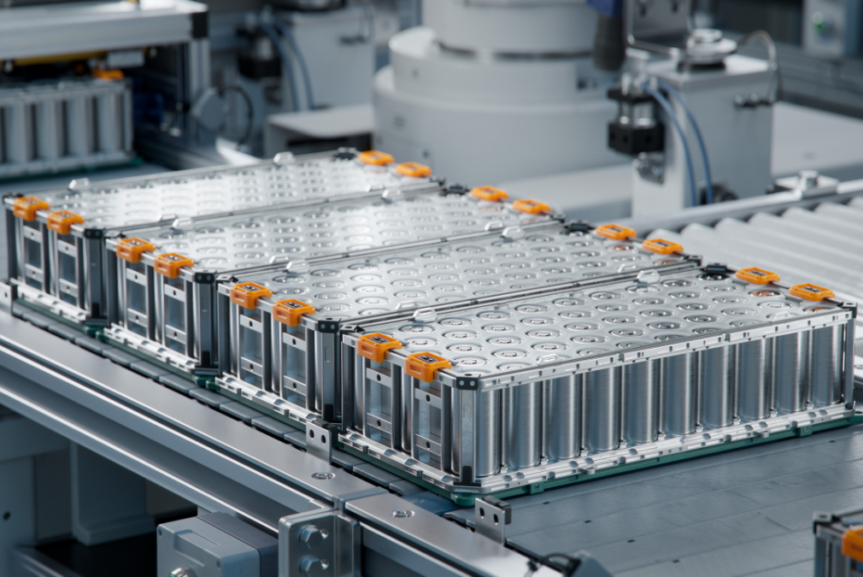

This story is based in the late 1980s when the world economy was booming and manufacturing industries, including that of lead-acid batteries (LAB) were flourishing. In one UK-based LAB factory, a decision to upgrade and modernise equipment had been taken. There was an overall budget and separate ones for each department. The key criteria for access to funds were to increase efficiency and cut costs. This was, of course, the age when computerisation and the paperless office were the twin pillars of modernisation for all businesses.

Our first management meeting involving all departments, to decide what slice of the budgetary cake we would each receive, was called by the MD, Geoff. The admin and sales requests were wrapped up early as they were predominantly based on computerisation and data handling. Most of the equipment and software was common to all finance, purchasing and sales departments. The main discussions centred on factory improvements. These were mostly about efficiency, throughput, automation, and in my case, product design and process streamlining.

One of the proposals, however, created a lot of excitement. This came from a young female engineer, Sally, and the proposal was a real humdinger. It was based on improving transformer efficiency to generate energy savings in the battery formation department. It was known that around a quarter of the formation equipment was quite old and used wire-wound transformers, rather than the more modern switch-mode rectifiers. Previous proposals to replace the old equipment with modern switch-mode models in order to improve productivity were rejected as not cost-effective. This, however, was based on energy efficiency, rather than production.

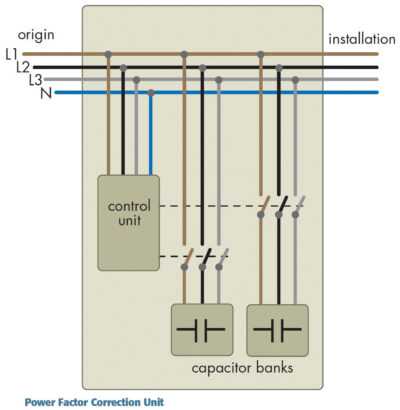

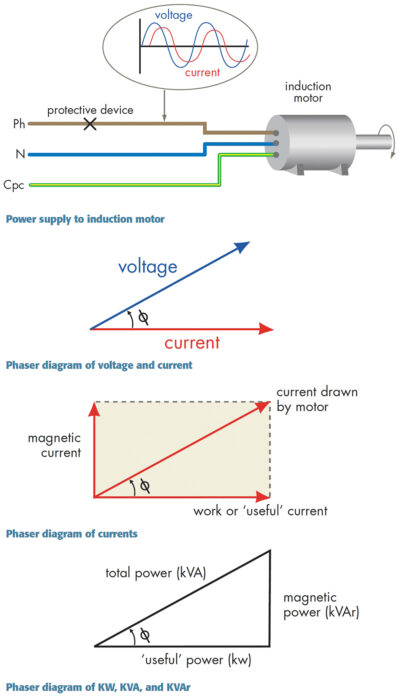

The installation costs and potential savings for manufacturing industries had not yet been established. Sally’s proposal, however, was very cheap, as it targeted a small inefficient section where it would have maximum impact. The cabling route could also be minimised, as could the size of the cables, making for a very low-cost installation. There were obviously many questions. The first came from the MD, Geoff: “Sally, can you tell me how this power factor works and how changing it can save energy?”

The answer was concise and right on the button.

“Without getting too technical, the old rectifiers use wire-wound coils to change the input power from AC to DC. This is based on induction rather than interruption and inversion, as with the chopper circuits in the switch-mode rectifiers. The induction method causes the alternating current for each phase of the incoming power to be out of step. The troughs and peaks of the three AC phases are not in sync and partially cancel each other out, which wastes energy. The 70% represents the proportion of power we get from the incoming 100%, to use in the processes. By putting in a PFC unit we lift that efficiency to over 90%, possibly 99% but easily 95%, to match the switch-mode rectifiers. In other words, we use at least 25% less energy.”

Geoff wanted to know more: “Can you give me some numbers to understand the scale of the saving? We are talking about improving only one-quarter of one production department after all.”

And this is where it hit home. Sally was well prepared: “OK, every year we put five million 12V 115 Ah (average) batteries through our formation department. Into each battery, we put five times the Ah capacity at around 17.5 volts per battery.

“This means we use 5 x 115 x 17.5 x 5 x106 Watt-hours of energy per year, just in the formation department. This works out to 50,312,500 units of electricity or £2,012,500 at four pence per unit.

“25% of that charging output is done on the old transformers, which works out at £503,125 per year. At 70% efficiency, it actually costs £718,750.

“If we reach just 92% efficiency with a locally placed PFC unit, we would use £546,875 of electricity.

“This is an annual saving of £168,875, or an extra 4% on the profit margin, all for a relatively small outlay.”

There was stunned silence for a few seconds, and then it seemed like the room exploded. The factory people saw it immediately, but admin, finance and sales did not believe it; even the company accountant was highly sceptical. They followed the numbers but did not believe the premise of the power factor correction. Sally sat down, rather shocked and embarrassed by the force of the reaction in the room.

“OK, OK that’s enough.” It was Geoff who waded in to bring back some degree of order. “I’ve heard of this being used and I know it can work.”

Geoff shook his head. “Seems too good to be true. Sally, how much and how soon?”

Sally had a rough estimate and a finger-in-the-air calculation for the delivery and installation.

“I’ve had ballpark estimates of between £95K and £120K for the complete installation, including commissioning. The completion date I’m not so sure; I wanted the approval before pushing companies on deliveries.”

“What’s your best guess?”

There was a deep intake of breath before the fateful words that she would later regret: “About four months.”

Ed and I audibly gasped and looked at each other. We tried to interject but were cut short by the MD.

“That’s enough. If Sally says four months then that’s what it is. We can leave a bit of latitude, as it’s a guess. But everyone, purchasing, maintenance, engineering etc. must give her the highest level of support. This project has a payback of less than a year. Every week missed, costs us £14,000. Think about that in the pub over the weekend. For my part, I intend to talk to an energy consultancy firm just to verify these numbers.” He looked over to Sally who seemed rather uncomfortable with all the attention. “No offence Sally, but I need to double-check before I give the go-ahead. Get your firm quotes and let me have them by the end of the week. I should get approval in a couple of days.”

And with that, we finished the meeting and filed out. Ed and I immediately caught Sally and took her to Ed’s office. We were both concerned by the short timescale. Neither of us could see this being completed in less than six months. We shared these concerns with Sally, who took a surprising view. Her position was that it was an important project and will save the company a lot of money. The sooner it was finished the sooner the savings will start.

Pressure had to be put on everyone otherwise it could drift and as Geoff had said, every week costs £14,000. It was this very point that I was making: Sally would be held responsible for the losses— not the savings— if the installation was substantially later than promised.

Unfortunately, she ignored the advice of the two older men, pinning her decision on the leeway already hinted at by Geoff. It seemed that we could not persuade her otherwise. And so, smiling, she left the room, assuring us that all would work out for the best.

Three months into the project, the company chosen to design and install the PFC units had not even had the materials delivered for their own manufacture. They had subcontracted the cabinet fabrication and had ordered the latest design of high-performance capacitors from a start-up company. In addition, most of the components were non-standard and the suppliers of both had fallen far short of their delivery promises.

Geoff called an emergency meeting when the bombshell that the project could go beyond six months finally emerged. At this meeting, all were held responsible for failing to keep the project on track. Sally was not singled out at this stage. Because Geoff had personally given delivery promises and scheduled savings to the head office, he was now under pressure and he needed results, not wisdom in hindsight.

The four-month milestone was passed, and the installation had not started. The latest information was not good. One of the installing company’s subcontractors had gone bust, without delivering the cabinets. It was at this point that Ed intervened. He used spare cash from his own budget to get a local sheet metal fabricator to make the cabinets to our specifications. It cost more than the originals but he was able to hide it in his own project costs and negotiated a reduction with the PFC company.

The summary result was that the project took five months and one week before switching on. The results were instantaneous, better than predicted, and clearly visible on the incoming meter. Ed and I monitored the results for one week before reporting the good news to the follow-up meeting. The meeting was uncomfortable: instead of celebrating the achievement, there was the feeling that we had been let down by poor project management. In my opinion, which I expressed, it was achieved more quickly than it would normally take to complete, and we had an extra month of savings rather than a shortfall.

Unfortunately, Geoff took a different view. We had made plans to leave a two-day gap in production at around four months and two weeks with subsequent loss in production output. Because of the delay, we incurred an additional output shortfall, due to having to repeat the exercise a month later. He had also based a presentation and advance report to the holding company’s board on achieving the savings from a four-month completion.

In fact, it was partially seen as a setback rather than the leap forward that it genuinely was. The view changed over time as the real savings kicked in, but unfortunately, a disillusioned Sally left a month after the project’s completion. Ed and I had attempted to explain to Sally that you have to carefully manage expectations in order to be seen to be successful.

If you promise completion in 10 days and you take 11, you have failed. If you promise completion in 12 days and you take 11, you are a success. Same result— totally different response. The sad truth is that what is best for the company is not necessarily what is best for an individual. Sometimes, you do have to think of yourself first.