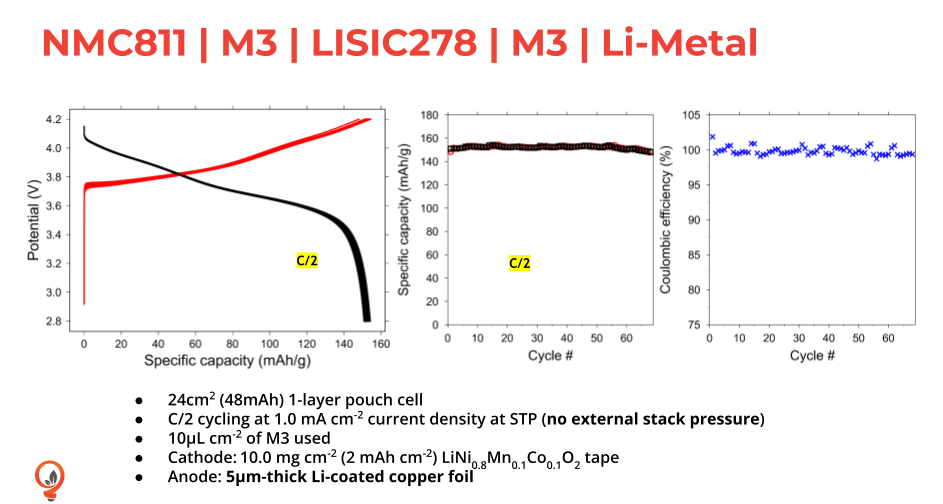

Natrion, a US solid-state EV battery component maker, said the results of its patented compounds in lithium-metal anode pouch cells demonstrated high C-rate capability and cycle life. This was without use of stack pressure.

We reported previously on Natrion’s patented solid-electrolyte separator in lithium-ion battery cells using graphite anode. Now, Natrion said it created new coin cells and pouch cells using a LISIC278 solid-state electrolyte separator and a lithium-metal anode. It comprised a 5-micrometer lithium-coated copper foil.

It also added its newest product, a solid electrolyte interphase-forming wetting agent, M3. It stabilises the Li-metal, suppresses dendrites and facilitates cycling at high coulombic efficiency without needing external stack pressure on the cell, the company said.

Test results:

- Near-zero fire risk

- 50%+ greater energy density vs state-of-the-art graphite anode due to improved volumetric and gravimetric efficiency (reduced total cell stack thickness)

- High cycle life and C-rate capability: 320 cycles demonstrated at 2C (30-min. charge time) and 100% depth-of-discharge with 98% retention

- 420-450 miles’ potential range on a single charge in an EV

- Viability to deliver without the use of stack pressure due to M3.

The company said “…while others in the industry have also demonstrated high cyclability, they have achieved this with either a much longer charge time or the use of significant external pressure.”

Image: courtesy Natrion