Canadian NEO Battery Materials has submitted its ninth patent regarding the manufacturing process of silicon composite anodes to the Korean Intellectual Property Office.

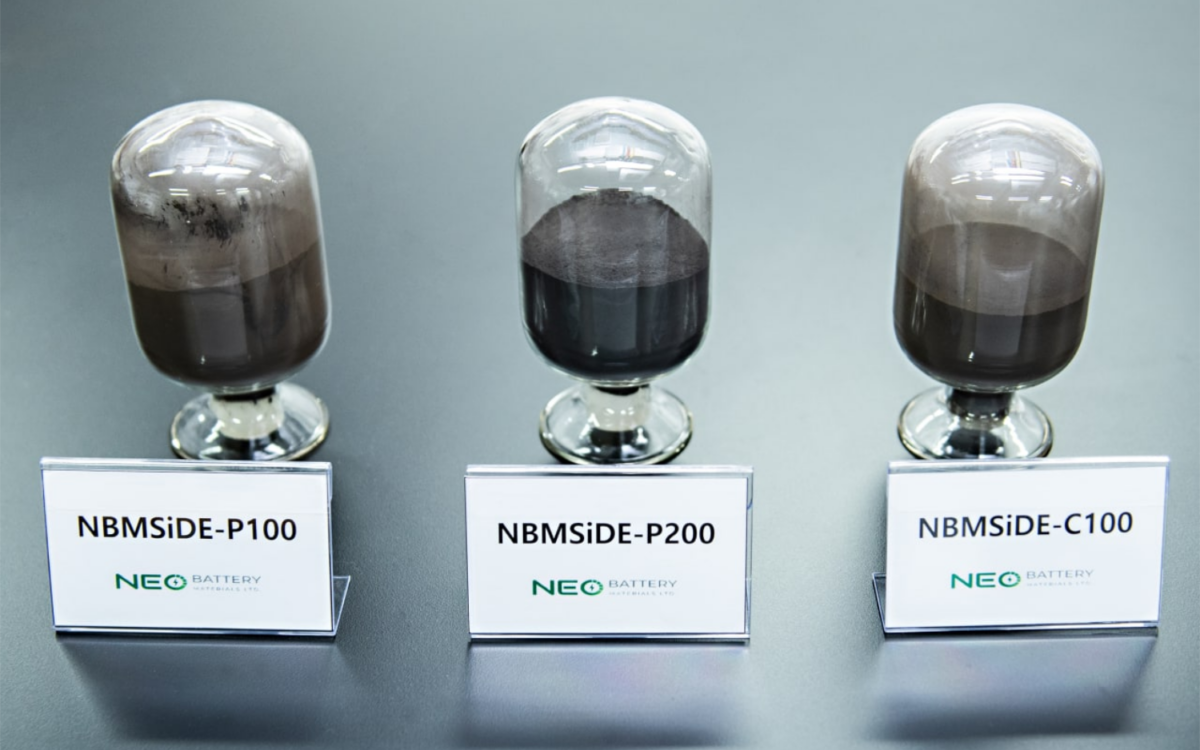

It said the patent, Silicone composite manufacturing method, protects a significant innovation in the manufacturing process of NEO’s proprietary silicon anode materials, NBMSiDE.

Unique additives that are effectively adsorbed on silicon particle surfaces have been employed to prevent silicon particles’ agglomeration or clustering effect by acting as an interparticle buffer layer during manufacturing.

This “technological advancement” boosts the production yield and cuts manufacturing costs, the company said. The particle size distribution allows increased uniformity and quality control, it added.

According to the journal Materials Science and Engineering, silicon is considered a promising anode material for lithium-ion batteries. The main reason is the high capacity of around 4000mAh/g, more than 10 times than for graphite anodes.

The first silicon carbon composite anodes were introduced in 2002 by a group of Asian and European researchers, who based their work on laboratory tests in the 1970s. First attempts to use silicon anodes failed due to swelling of the material in loaded state, causing fracturing and crumbling of the silicone material. Instability of the solid electrolyte interphase layer (SEI), which determines the capacity of energy storage, has also been observed.

However, NEO claims that its researchers have solved several of the problems by developing the unique additives. The R&D scale-up centre in South Korea will continue to improve and commercialise the manufacturing process of NBMSiDE.

The technology employs elastic nanocoating materials to encapsulate the entire surface area of the silicon particles. NEO is aiming for a portfolio of 20+ patents during 2024.

The new anodes will be used in lithium-ion batteries for EVs, electronics and energy storage systems. The target is to develop a 1,000 mile EV battery, it said. NEO said that the trend towards cheaper LFP short-range batteries can be offset by using silicon anodes.

Tests have also been made to study ultrafast charging of the lithium-ion batteries equipped with silicon composite anodes, even down to five minutes. Leading EV manufacturers, including Tesla and Porsche, have tested the new technology.

Photo: NEO’s proprietary silicon anode materials, NBMSiDE