Indian firm Exide Industries aims to produce the country’s most technically advanced lead-acid battery to date at its new state-of-the-art automotive battery making facility.

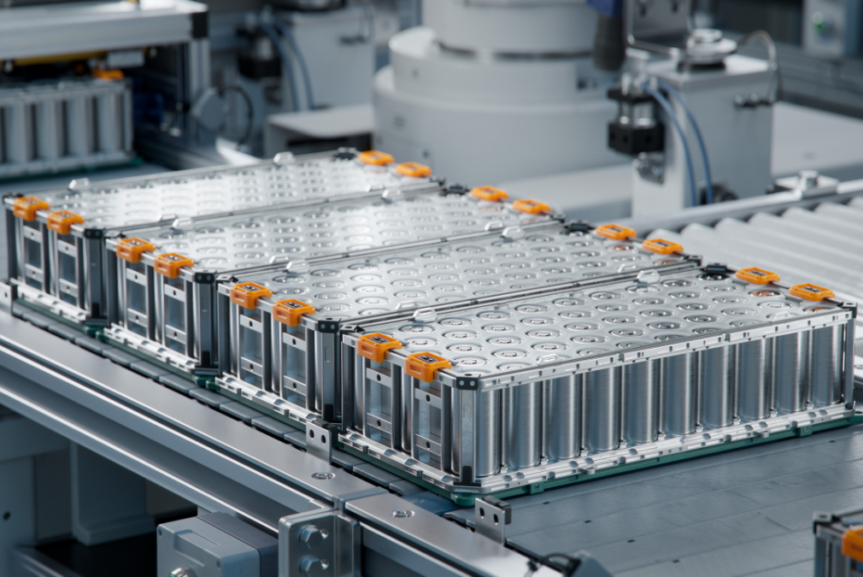

The INR 7,000million ($100 million) unit in West Bengal will use punched grid technology, rather than expanded metal technology, to manufacture Exide’s new range of automotive batteries.

The facility, which will manufacture batteries for two-wheelers, was built with technical collaboration from US firm East Penn Manufacturing Company.

Exide expects the new technology to raise the plant’s capacity by 1.3million units to 3.5 million units a year.

The company is also expected to invest another INR 3,000million ($44 million) in the facility over an 18-month period from April 2017.

The company has also asked the West Bengal government to make a suitable site available in the state to set up a lead-smelting plant at a cost on INR 1,200 million ($18 million).

Exide’s managing director and CEO, Gautam Chatterjee, said the company had spent seven years pioneering advances in its lead-acid batteries to enable it to boost product reliability.

He added: “The new range of batteries will be a lot more robust, as being manufactured in a modern plant with advanced robotics and automation, and this procedure also succeeds in eliminating human errors to a large extent.”

The India firm inaugurated the new facility at its 41 acre Haldia Factory, which was first established in 1981 to make automotive and industrial batteries.

India’s chief minister Mamata Banerjee opened the plant, the third in West Bengal and 11th in India, on January 2nd.

The Haldia factory accounts for 30% of the company’s overall business. Exide’s other battery making factories are in Shamnagar (West Bengal), Hosur (Tamil Nadu), Chinchwad, Ahmednagar and Taloja in Maharashtra, Bawal (Haryana), Pune, Uttaranchal and Bangalore.