There is no doubt that there are 1,000’s of tonnes of used lead-acid batteries around the world that should be recycled safely and effectively. Doug Lambert, vice president sales and technology at Wirtz, discusses this, with a focus on the need for small-scale processes that are environmentally responsible and provide hygienic methods for the recovery of lead.

In India, after 2001, when Batteries (Management & Handling) Rules was enacted, and an authorisation scheme for green recyclers, regulating auctions, etc., was put in place, the informal recycling of used lead-acid batteries started declining.

Recent information from the India Lead Zinc Development Association (ILZDA) in Delhi, would indicate that although the large battery manufacturers in India are putting maximum pressure on their dealers to return used lead-acid batteries (ULABs), with a corresponding increase in the rate of recovery, the current industry estimate is that informal recycling is still around 30%.

Data published in India’s Economic Times states that despite India’s drive for urbanisation, only 22 people out of a thousand own a car.

United Nations data puts the current population of India at ~1.38 billion.

Assuming an estimated average car battery life of ~2.0 years, then ~15.2 million car batteries (~250,000 tonnes) are replaced every year and ~75,000 tonnes of car and truck batteries are handled by the informal sector.

India has the largest number of motorised 2-wheelers in the world with an estimated 37 million motorcycles/mopeds; and ~18 million new motorcycles were sold in India during 2020. It is quite possible, given their small size and weight (12V7Ah ~3kg), that the majority of these 2-wheeler batteries could be being recycled by the informal sector. However, if we again assume an average battery life of two years, and a 70% recovery by the regulated sector, then this huge sector of the battery market results in a further ~8,000 tonnes needing to be reprocessed by the informal sector.

India is home to about 1.5 million battery-powered, three-wheeled e-rickshaws. As many as 11,000 new 3-wheelers hit the streets every month, and annual sales are expected to increase about 9% by 2021. Typically, each e-rickshaw has four, 100Ah lead-acid batteries, each weighing ~22kg, and again assuming at best a one-year average battery life, and 70% recovery; this sector of the mobility market adds another ~40,000 tonnes.

There are numerous other applications for lead-acid batteries such as: small solar home systems, inverter power packs, solar refrigerators and freezers, water pumps etc., and the demand for batteries is increasing. There are ~175,000 off-grid solar water-pumps in India, and under the government Kisan Urja Suraksha evam Utthaan Mahaabhiyan (KUSUM) scheme, this is planned to increase 10-fold by 2022.

India consumes a total of ~1.2 million tonnes of lead per year, of which ~1.0 million tonnes is used in the battery industry.

Currently ~0.8 million tonnes of the total is from ‘secondary’ recycled lead, of which ~240,000 tonnes is from the informal sector.

A used 12V lead-acid battery typically weighing 16-18kg will only contain ~5kg of metallic lead ie. ~30% of the total mass.

Sadly, there is not the necessary recycling infrastructure in many parts of the country, and the process of recovering lead from used batteries in the informal sector leads to environmental lead pollution from the disposal of lead-pastes (typically ~35% of the total battery mass), and chronic health problems from ‘lead poisoning’ through ingestion and inhalation of lead dust and fumes.

It is reasonable to assume, therefore, that the ~240,000 tonnes of ‘informal’ recycled lead in India is from more than 800,000 tonnes of used lead batteries, which have been broken-up manually, every year, by thousands of unfortunate people with no other option to earn a living.

Every used lead-acid battery, everywhere in the world, has a ‘value’ and should be recycled safety and efficiently.

Battery Recycling Systems as part of the Wirtz Group of companies has recently responded positively to this need (‘challenge’) with the development of the worlds’ first small-scale recycling system, the ‘RTR’ or ready-to-run system.

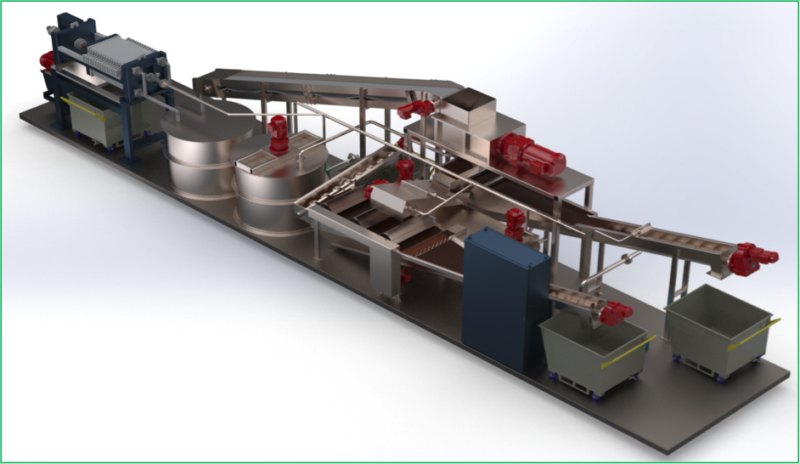

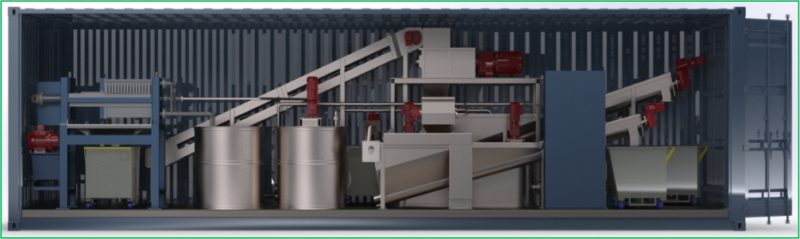

The RTR is a complete small-scale breaking and separation system for used lead-acid batteries.

It is a compact design, fully assembled as a skid-mounted system that fits into a single 40-foot high-ceiling shipping container, so that it arrives ready to run.

The RTR system can be combined with novel ‘green’ lead and lead paste (leady oxides and sulfates) recovery processes such as Solveteq’s DES solvent treatment, and FenixPb (Aurelius Environmental) or Citrecycle’s citric-acid based hydro-metallurgical processes.

Customers, worldwide, will receive a unique, complete lead-acid battery recycling solution that is modular, scalable, and offers a greener, cleaner, safer and more effective solution to recycling used lead-acid batteries, particularly in the informal sector.