Researchers have come up with a system for finding the best lithium-ion battery electrolyte using robotics and AI. They say finding the correct electrolyte is six times quicker and the pouch cells demonstrated improved fast-charging capability.

The study was published in the journal Nature Communications. The paper said in the case of non-aqueous battery electrolyte solutions, the many design variables in selecting multiple solvents, salts and their relative ratios make electrolyte optimisation time-consuming and laborious.

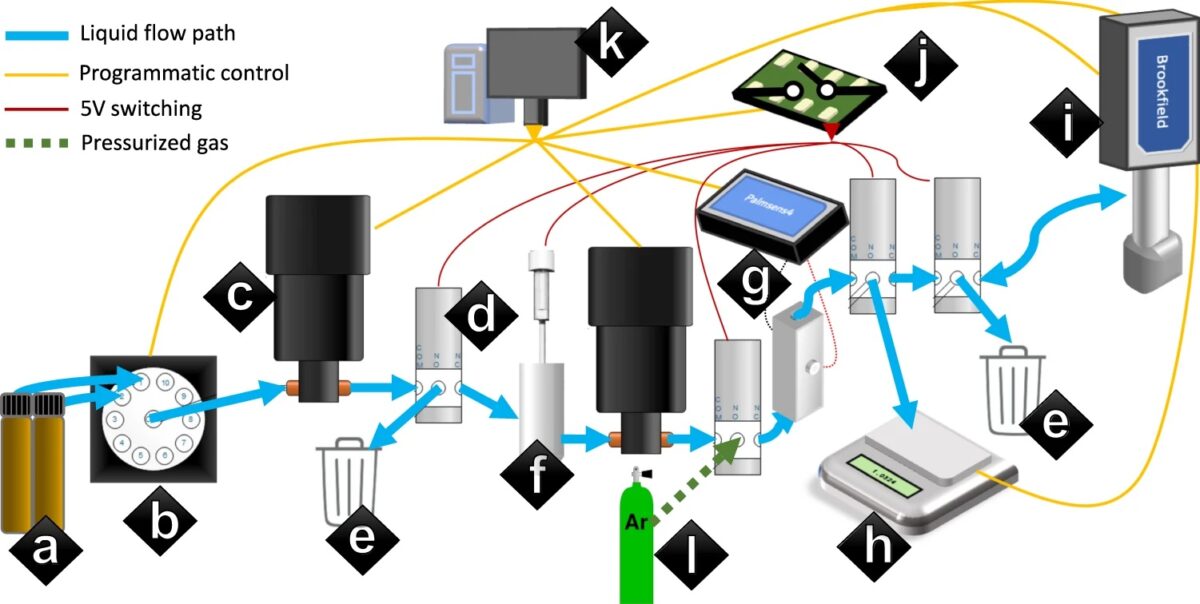

To overcome this, they came up with an experimental design that couples robotics (a custom-built automated experiment named “Clio”) to machine-learning (a Bayesian optimisation-based experiment planner named “Dragonfly”).

An autonomous optimisation of the electrolyte conductivity over a single-salt and ternary solvent design space identified six fast-charging non-aqueous electrolyte solutions in two working days and 42 experiments.

“This result represents a six-fold time acceleration compared to a random search performed by the same automated experiment,” they said.

They tested the practical use of the electrolytes in a 220 mAh graphite∣∣LiNi0.5Mn0.3Co0.2O2 pouch cell configuration. All the pouch cells containing the robot-developed electrolytes demonstrated improved fast-charging capability against a baseline experiment using a non-aqueous electrolyte solution selected a priori from the design space.

The researchers said the result “demonstrates the potential of closed-loop experiments to discover optimal material designs within well-explored and unexplored design spaces”.

They believe this work will be useful beyond the battery community: “Our custom-designed robotic platform, experiment planning, and integration with device testing will be valuable in optimising other autonomous discovery platforms for energy applications and material science in general,” they said in the study.

Figure: Schematic diagram of automated electrolyte experiment, “Clio”.