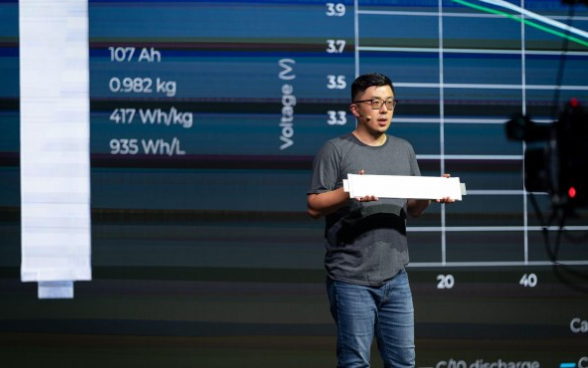

Battery firm SES (formerly known as SolidEnergy Systems) has launched a 107Ah lithium-metal battery for the automotive industry.

The Apollo cell will be manufactured at SES’ 1GWh lithium-metal Shanghai Giga facility, which is being built in Shanghai, China.

The 300,000 square-foot facility is scheduled for completion in 2023, with the company aiming to start commercialisation of lithium-metal batteries two years later.

The firm says the battery weighs 0.982kg, and has a specific energy of 417Wh/kg and energy density of 935 Wh/L.

SES said the battery demonstrated similarly high capacity and energy density when tested at C/10 (10 hour discharge), C/3 (three hour discharge), and 1C (one hour discharge) at room temperature.

SES’s hybrid Li-Metal batteries use a high-energy-density lithium-metal anode, a protective anode coating, a proprietary high-concentration solvent-in-salt liquid electrolyte, and artificial intelligence safety features.

Vehicle OEM test samples

SES is working with vehicle OEMs GM and Hyundai to deliver practical automotive A-samples next year— a first for the industry.

The announcements were made at SES Battery World, the company’s inaugural Battery World virtual event that took place in the US on 3 November, and in South Korea and China on 4 November.

Dr. Qichao Hu, founder and CEO, SES, said: “There’s a race among leading global carmakers and next generation battery suppliers to develop and demonstrate the world’s first 100Ah Li-Metal battery.

“We did it. We will continue to work with our OEM partners to optimise this battery and bring it to commercial production. We are confident that we and our OEM partners will win this race, and be the first to commercialize this next generation Li-Metal battery.”

The batteries will need to go through further testing and optimisation, to ensure they are capable of delivering high energy density over a wide range of temperature and power density.

SES also introduced its three parallel development tracks: Hermes (platform for material development), Apollo (engineering capability for large automotive cells), and Avatar (AI-powered safety software to monitor battery health).

Hu said: “The industry doesn’t need another battery breakthrough. What the world needs is someone who can take a battery breakthrough and make it work, truly, practically and completely, and then scale it up into hundreds of thousands and millions of vehicles. That’s what we’re here to do.”

Bob Galyen, owner of Galyen Energy and Former CTO of CATL, said: “Of all the public claims of new battery technologies, SES is the first which I am aware of to achieve large cell format Lithium metal anodes.

“With SES’s unique electrolyte-salt combination they have created a cell which has superior safety, impressive performance, achieved respectable life and utilises nearly the same manufacturing processes as used by the Lithium-Ion manufacturers today.”

Founded in 2012 as a spin-out company of the Massachusetts Institute of Technology, SES operates two battery-prototyping facilities in the U.S. and China.

Stock market listing

In July, SES announced plans to list on the New York Stock Exchange (NYSE) through a merger with Ivanhoe Capital Acquisition Corp.

Upon the closing of the transaction, the combined company will be listed on the NYSE under the new ticker symbol SES.