Testing to see how battery maker Axion Power International’s lead-carbon technology handles ‘real world’ driving conditions is due to begin this month.

The US firm has already shipped its PbC® Batteries to the Battery Innovation Centre of MOBI Research Group at the Vrije Universiteit Brussel (Free University of Brussels)in Belgium.

The centre will evaluate the batteries in automotive applications based on real world driving conditions and EU vehicle types for an unnamed multinational automotive supplier.

Lead-carbon is seen as a way to bringing a cheaper stop-start technology to the mass market as the industry looks to combat increasingly tight emissions regulations.

The technology’s ability to charge and discharge quicker is seen as key to its adoption by OEMs.

Professor Noshin Omar, head of the Battery Innovation Center at Vrijie Universiteit Brussel, will be running the independent third party validation.

The tests are seen as a way to benchmark PbC Battery performance and its against different battery chemistries for vehicle applications.

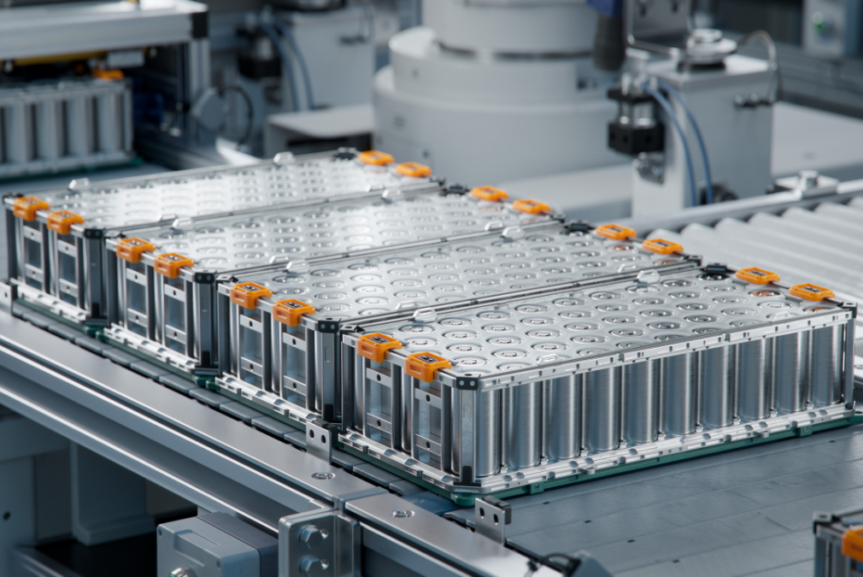

The Battery Innovation Centre of MOBI Research Group offers state-of-the-art testing facilities and modeling for rechargeable energy storage systems. It is the main Belgian center for research and development of energy storage systems for traction and stationary applications.

“We are pleased to partner with the Vrijie Universiteit Brussel on this project in the advancement of hybrid vehicle development,” said Richard Bogan, CEO, Axion Power.

“This work effort is one of many projects currently underway around the world to establish the unique features and robust capability of Axion’s proprietary PbC Technology.”