Lithium

Latent-IQ launched to cut EV battery recalls

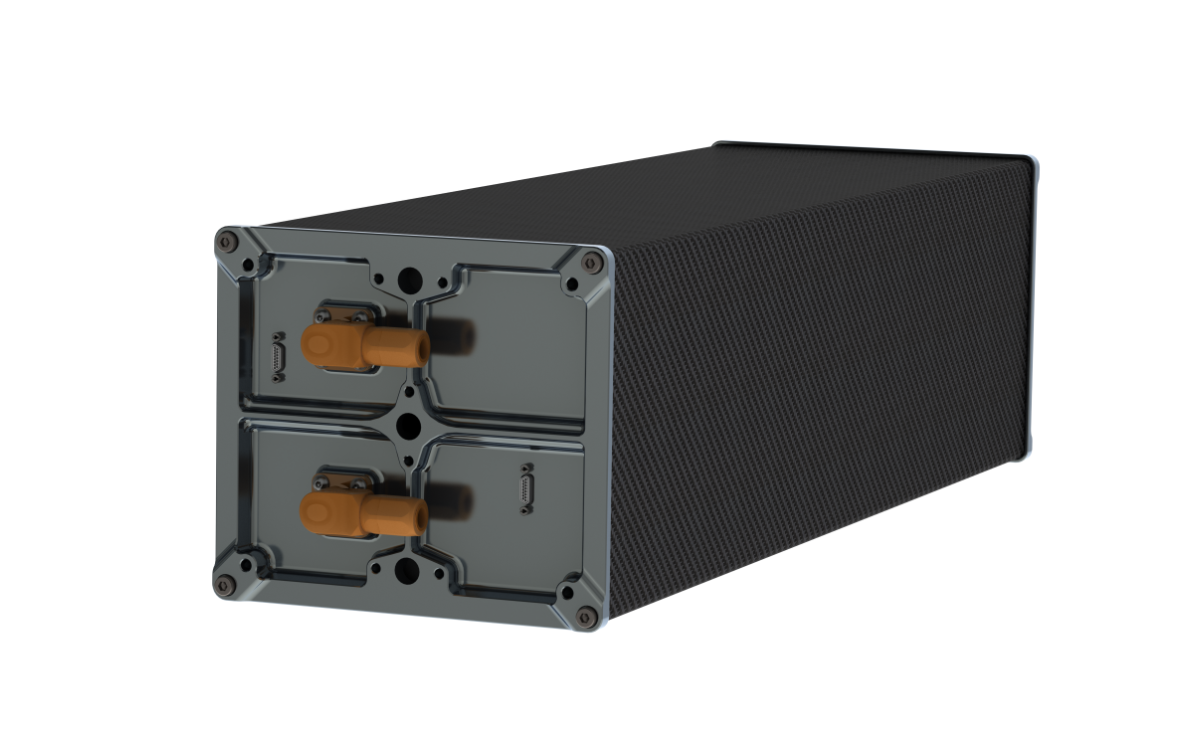

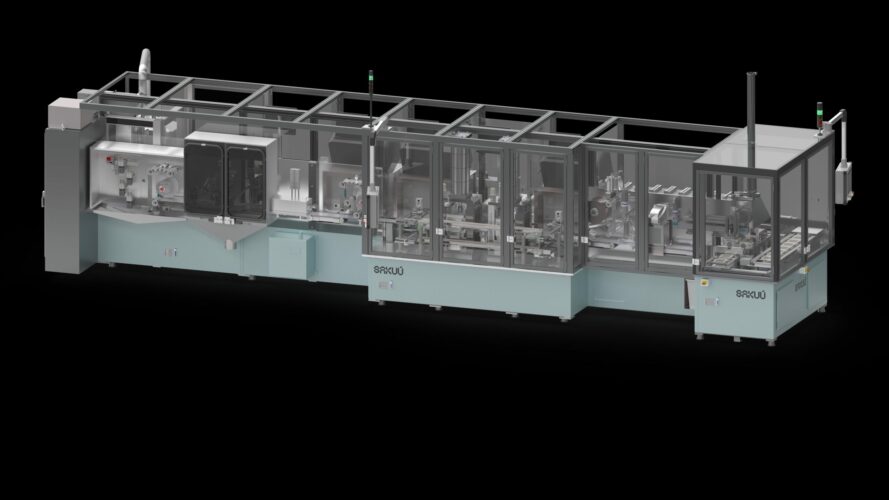

Autocraft EV Solutions has unveiled Latent-IQ, a new diagnostic tool within its OptEVizer platform, designed to help OEMs detect hidden faults in high-voltage EV batteries before they lead to costly...